What is PCB Drilling Compensation?

In the PCB drilling process, rpttechpcb drills out the holes according to the custom requirements and then plated the PTHs (plated through-holes), however which will lead to a reduction of the effective diameters of the holes. In order to ensure the finished hole diameters meet the requirements, our engineers will go PCB drilling compensation, based on IPC 2-3 standards.

How Do We Compensate the Drilling Holes in PCB?

In order to give a clearer understanding, let us talk about some key parameters for PCB drilling compensation here:

1. Drilling bit system

Depends on the PCB manufacturers' purchasing plans, the routine is 0.05mm. Generally, the size ranges of the drill bits is between 0.1mm and 6.35mm, thus the diameters are such as 0.10mm, 0.15mm, 0.20mm. . . .

2. Compensation value

The compensation value is formulated by the PCB factory' capacity together with the multiple test results. Actually, the PCB drilling compensation values of the whole industry almost the same, as below.

3. Drilling strategy

The strategy of selecting PCB drilling bits is formulated by the engineers according to diameter requirements and production capacity. The selection strategy follows rounding, 0.02mm is the threshold value. For example, the finished hole diameter is 1.025mm, 0.10mm of PCB drilling compensation is required, so the actual drilling should be 1.125mm, but we do not have a drilling bit of 1.125mm, so let's follow the selection strategy, 1.125mm mantissa is 0.025mm, while 0.025mm>0.02mm, it gets rounded up to 0.05mm, we choose drilling bit of 1.15mm.

Actually, not only for the drilling Holes in PCB, compensation of the circuit traces or pads is also the necessary process in PCB manufacturing, all of the CAM processes will change the original files more or less, but which totally aims to output your boards correctly, so it is appreciated if you understand this and spend few minutes to check the working Gerber before production

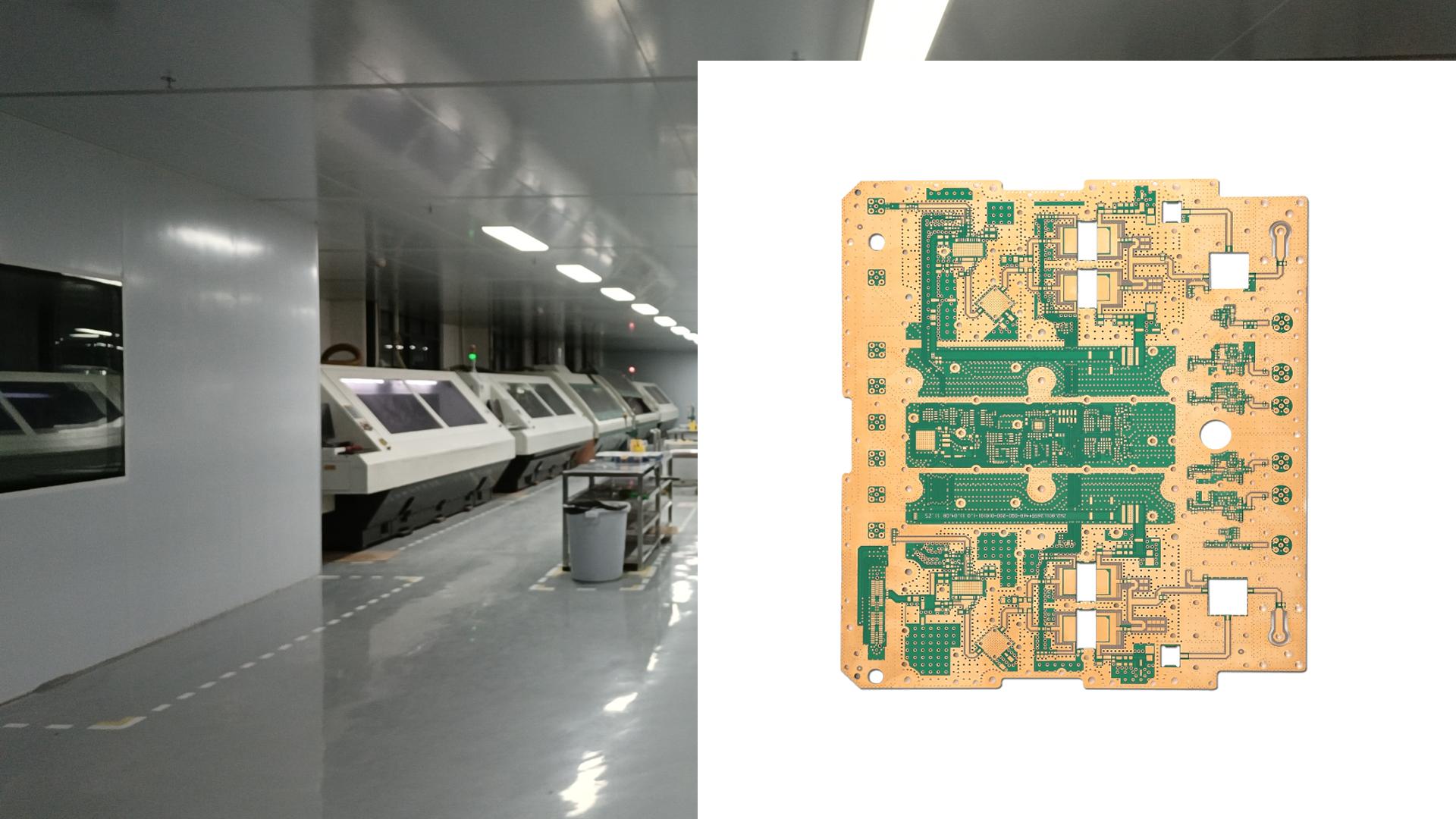

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd