1. What is a multilayer PCB?

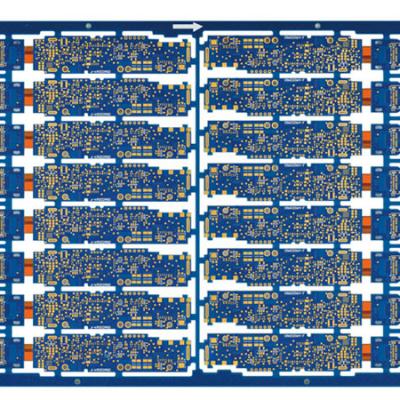

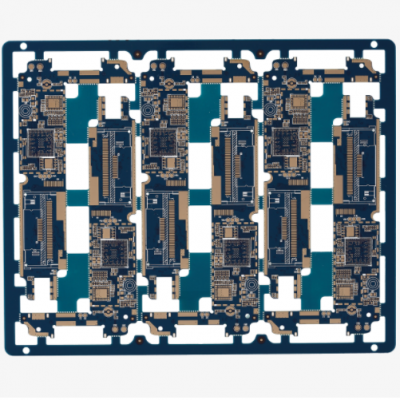

In order to meet the space and weight constraints of modern electronic equipment, it is necessary to use multilayer PCBs, which, as the name suggests, consist of multiple layers of material laminated together to form a single circuit board. Multilayer PCBs are manufactured using high pressure and temperature conditions to allow the layers to bond tightly to each other and to avoid air bubbles within the board.

Uses and benefits of multilayer PCBs

As modern electronics become smaller in size and more complex in function, multilayer PCBs offer many distinct advantages over single-layer PCBs, particularly in the following applications:

Data storage, satellite systems, mobile communications, signal transmission, industrial control, space equipment, nuclear detection systems

The advantages of using multilayer PCBs in these applications include:

1. multilayer PCBs handle more circuits than single- or double-sided PCBs, provided that the board area is the same. The high assembly density of multilayer PCBs makes them suitable for high-capacity and high-speed applications in complex systems. 2.

2. The small size and light weight of multilayer PCBs make them ideal for equipment with space and weight constraints.

3. Multilayer PCBs are highly reliable. 4.

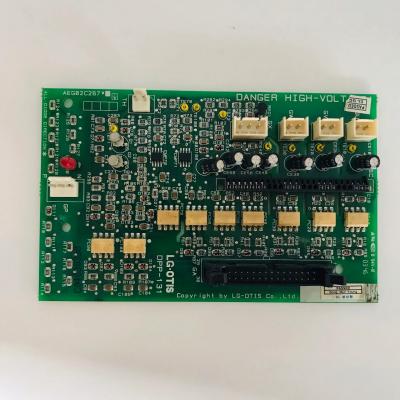

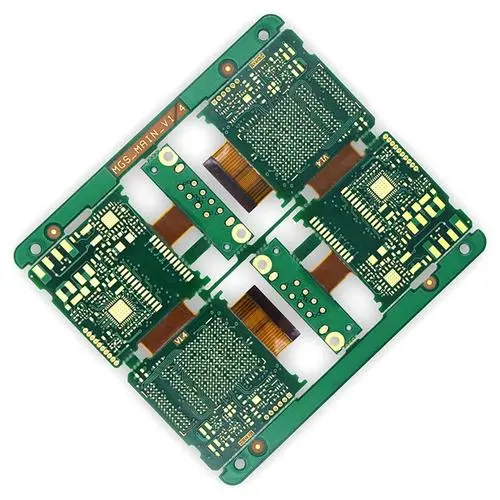

4. Multilayer PCBs are flexible and can be used in circuit structures that require bending.

5. Multilayer PCBs can withstand high temperatures and pressures and can be used in equipment where the durability characteristics of the circuit are important.

6. Controlled impedance routing is easy in multilayer PCBs.

7. The power and ground layers in multi-layer PCBs help to achieve EMI shielding. 2.

2. Thermal stress in multilayer PCBs

When making multi-layer PCBs, semi-cured sheets and core material layers are stacked together. The conductors are encapsulated in a resin material and the layers are bonded together with adhesives. All materials involved in a multilayer PCB have different rates of thermal expansion and contraction, known as the coefficient of thermal expansion (CTE). the difference in CTE and the increase in temperature result in a temperature field and a thermal stress field in the multilayer PCB. High thermal stresses can cause PCB deformation and lead to serious problems in circuit operation, reliability and lifetime.

3. The importance of thermal stress analysis of multilayer PCBs

Thermal stress analysis is a coupled temperature and stress field analysis on a multilayer PCB that uses thermal stress analysis to analyse the effects of high and low temperature cycling on the circuit components and operation. The physical layout of the multilayer PCB is then modified based on the results of the thermal stress analysis, which helps to reduce the temperature and thermal stress fields of the multilayer PCB.

Thermal stress analysis is helpful in a number of ways, including

1. placing devices according to the temperature stress and shear on the solder joints of the multilayer PCB.

2. predicting the chances of delamination and micro-cracking in multilayer PCBs. 3.

3. predicting whether deformation will occur in multilayer PCBs.

When designing optimised multilayer PCBs, the results of the thermal stress analysis are very useful to effectively reduce temperature and stress extremes in multilayer PCBs and also to improve the thermal reliability, physical board robustness and lifetime of multilayer PCBs.

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd