The rational layout of electronic components on the PCB is an extremely important part of reducing soldering defects! Components should avoid areas with very large deflection values and high internal stress areas as much as possible, and the layout should be as symmetrical as possible.

In order to maximize the use of circuit board space, I believe that many design partners will place components as close to the edge of the board as possible, but in fact, such an approach will bring great difficulty to production and PCBA assembly, and even lead to Unable to weld and assemble!

Today, I will talk to you in detail about the layout of board-side devices~

Board edge device layout hazards

1. Edge milling of forming board

If the components are placed too close to the edge of the board, the pads of the components will be milled off when forming the milling board. Generally, the distance between the pads and the edge must be greater than 0.2mm, otherwise the pads of the edge components will be milled off and cannot be soldered after assembly. components.

2. Forming board edge V-CUT

If the edge of the board is imposition V-CUT, the components need to be farther away from the edge of the board, because the V-CUT knife passes through the middle of the board. Generally, the distance between the components and the edge of the V-CUT board should be more than 0.4mm, otherwise the V-CUT The CUT knife will damage the pad, making the components unable to be soldered.

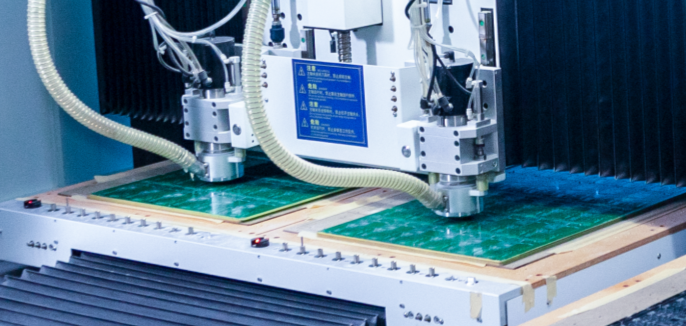

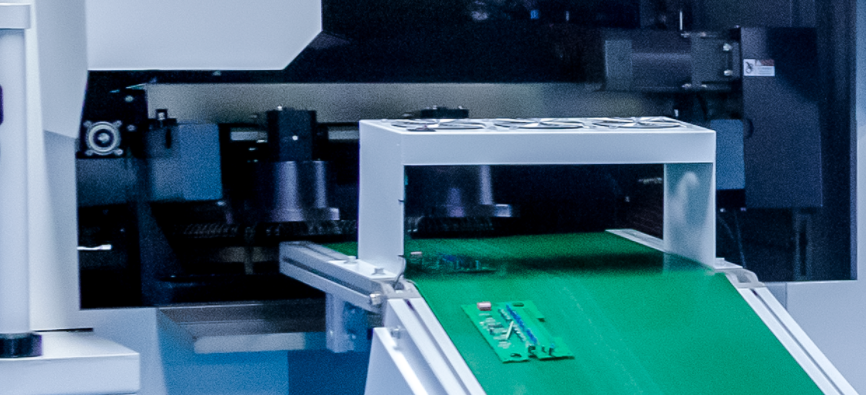

3. Component interference equipment

Component placement too close to the edge of the board during design may interfere with the operation of automated assembly equipment, such as wave soldering or reflow soldering machines, when components are assembled.

4. The equipment crashes the components

The closer the components are to the edge of the board, the greater the potential interference of the components to the assembly equipment. For example, components such as large electrolytic capacitors, because the electrolytic capacitor components are relatively high, such components should be farther away from the circuit board than other components. edge placement.

5. The sub-board damages the components

After the product assembly is completed, the imposition products need to be separated off the board. During separation, components that are too close to the edge may be damaged. This damage may be intermittent and difficult to find and debug.

Let me share with you a production case about the insufficient distance between board edge devices and damage.

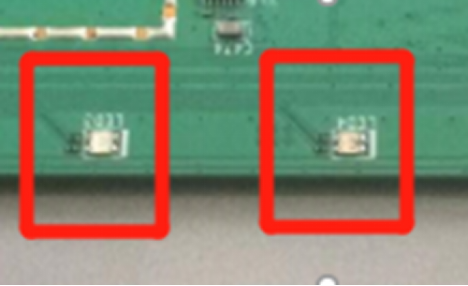

Problem Description

When a product was placed in SMT, it was found that the LED lamp was close to the edge of the board, and it was easy to be bumped during production.

problem impact

During production and transportation, and when the DIP process passes through the track, the LED lamp will be damaged, which will affect the function of the product.

question extension

It is necessary to modify the board to move the LEDs into the board, and at the same time, it will also involve the modification of the structural light guide column, which will seriously delay the project development cycle.

Board edge device risk detection

The importance of component layout design is self-evident. It can affect welding at least, or directly cause device damage. So how to ensure zero design problems and successfully complete production?

RPTtechpcb DFM assembly analysis function, with inspection rules defined according to the parameters of the component type and the edge of the board, there are also exclusive inspection items for the layout of components on the edge of the board, high components to the edge of the board, short components to the edge of the board, and guide rails from the device to the machine Multiple detailed inspection items such as edges are sufficient to meet the design requirements and evaluate the safe distance between the device and the edge of the board.

After the PCB drawing design is completed, directly use RPTtechpcb DFM to check the assemblability, which can avoid the damage of the components on the edge of the board, and the components on the edge of the board will affect the operation of the production equipment during the assembly production process. Production problems, and avoid them in advance, reduce costs and improve efficiency!

we supply low-cost PCB,Cheap PCB, Low price for PCB,94V0 PCB

Its assembly analysis function has 10 major items and 234 detailed inspection rules, covering all possible assembly problems, such as device analysis, pin analysis, pad analysis, etc., and can solve various production situations that engineers cannot predict in advance.

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd