What factors need to be considered when designing a switching power supply PCB? How to Design a PCB

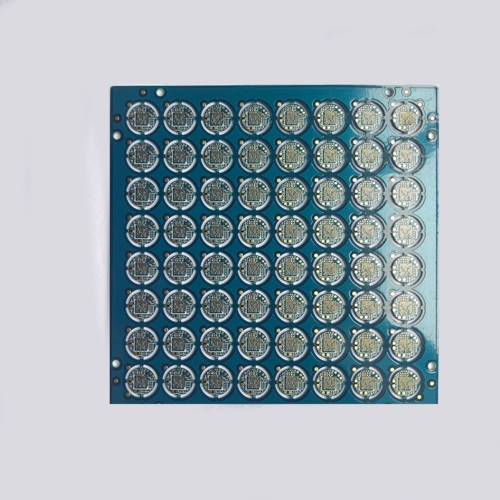

First of all, the input, output, and power efficiency of the power supply should be considered, and its voltage and current limitations should be considered to ensure circuit safety and reliability.

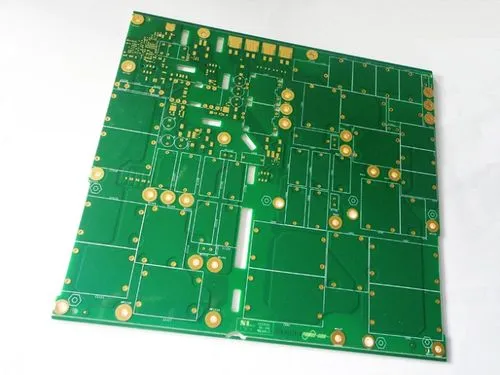

Secondly, consider the size of the PCB board to ensure that the PCB board has enough space to arrange all the components without affecting the efficiency of heat dissipation and power supply. In addition, the withstand voltage of the PCB board should be considered to ensure that the circuit can work normally under high voltage conditions, so as to reduce the impact of leakage on other components when the power supply fails.

In addition, parameters such as power supply output ripple and noise can be considered to ensure the quality and performance of the switching power supply. Designing a PCB board requires making choices on a case-by-case basis to ensure the integrity and accuracy of the design.

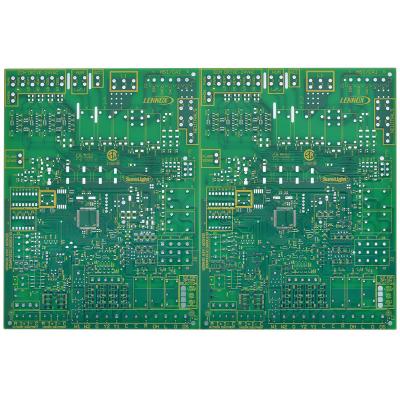

First of all, the design of the switching power supply should determine the package type and size of the components according to the required voltage and current range, so as to ensure the reliability of the circuit.

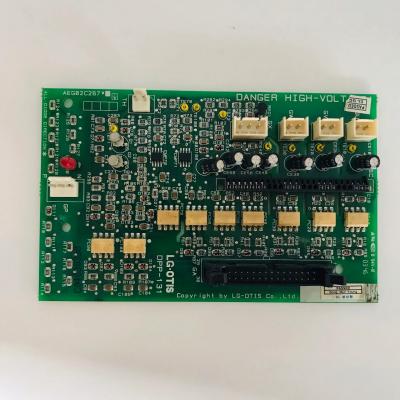

Secondly, it is necessary to design a complete power supply circuit on the PCB board, including voltage regulation circuit, voltage stabilization circuit, filter circuit, etc., to ensure that the output ripple and noise of the switching power supply meet the requirements.

In addition, to achieve thermal efficiency and power efficiency, it is also necessary to consider the layout of heat dissipation components on the PCB and the heat dissipation performance requirements of the power circuit.

Finally, a reasonable PCB board layout should be designed in combination with the component packages that can be supported on the PCB board to ensure that the switching power supply is small in size and does not affect the safety and reliability of the components.

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd