If the height of the component is not set correctly during the SMT production process, it may cause the following effects:

1. Inadequate adhesion of components: If the height of the components is too high or too low, the bonding between the components and the PCB board will not be strong enough, which may cause problems such as component falling off or short circuit.

2. Component position offset: If the component height is not set correctly, it will cause component position offset during the placement process.

3. Low production efficiency: If the component height is not set correctly, it may lead to a decrease in the operating efficiency of the placement machine, thereby affecting the efficiency of the entire production process.

4. Component damage: Due to the wrong height and wrong servo control position, the placement pressure is too high and the components are damaged.

5. The PCB stress is large and the deformation is serious, causing damage to the circuit, and eventually causing the entire board to be scrapped.

6. The difference between the set height and the actual height is too large, resulting in flying pieces.

Therefore, in the SMT production process, it is very important to set the height of the components correctly. You can adjust the height setting of the placement machine to ensure the correct bonding and position of the components

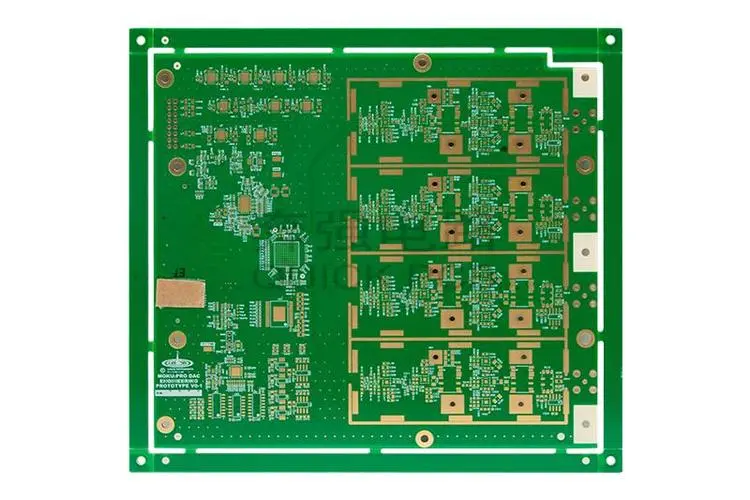

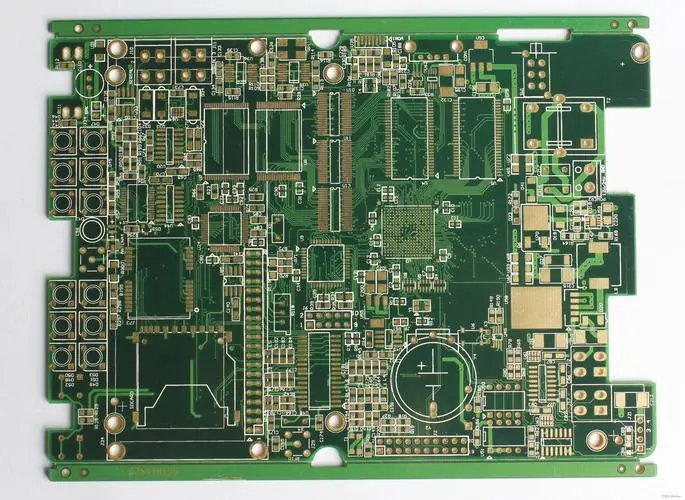

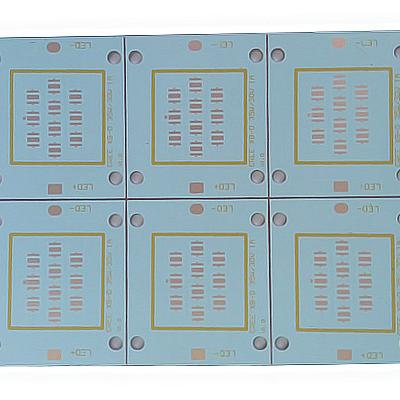

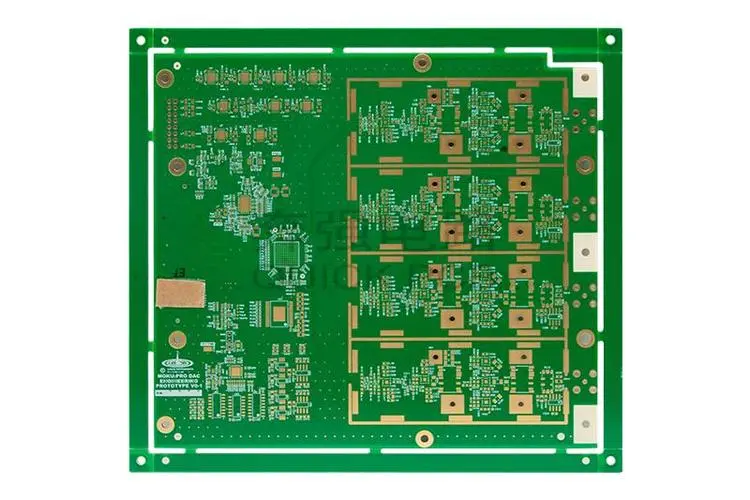

rpttechpcb is Professional production low-cost PCB,Cheap PCB, Low price for PCB,94V0

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd