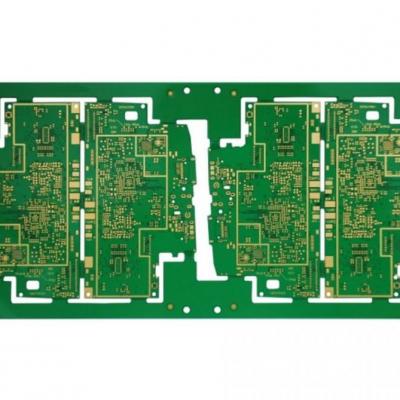

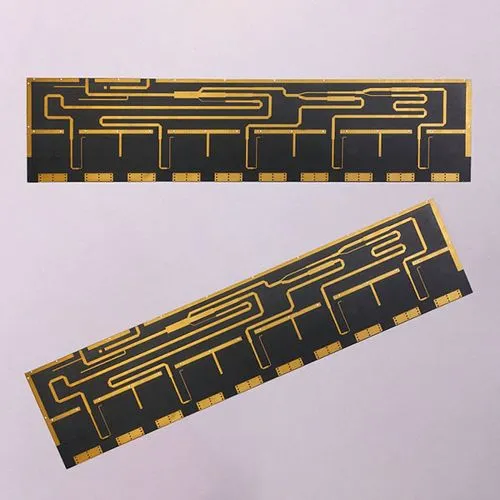

Each rigid and flexible aluminum -based plate design is different, customizing the purpose of satisfying customers. The same is true of PCB substrate -glass fiber is a common substrate, but aluminum substrates are also very effective in many applications. The aluminum substrate consists of a metal -based copper layer, which provides high performance, including excellent thermal conductivity and electrical insulation. The aluminum substrate is a metal substrate, and its structure is divided into three layers:

The aluminum substrate is also called the metal base PCB, and it consists of a metal base layer covered by the copper foil circuit layer. They are made of alloy plates of aluminum, magnesium and silicon aluminum (Al-Mg-SI). The aluminum substrate has excellent electrical insulation performance, good thermal power and high processing performance. The difference between them and other PCBs is in several important aspects.

The grassroots are composed of aluminum alloy substrates. Use aluminum to make this type of PCB a great choice for Tongkou technology

The heating layer is an important part of PCB. It contains a ceramic polymer, which has excellent viscosity, excellent heat resistance, and prevents PCB from resisting heat and mechanical stress.

The circuit layer contains the above copper foil. Generally speaking, the copper foil used by PCB manufacturers from 1 to 10 ounces.

The electronics layer of the insulator absorbs calories with the current flow over the circuit. Move it to the aluminum layer, and the heat dissipation.

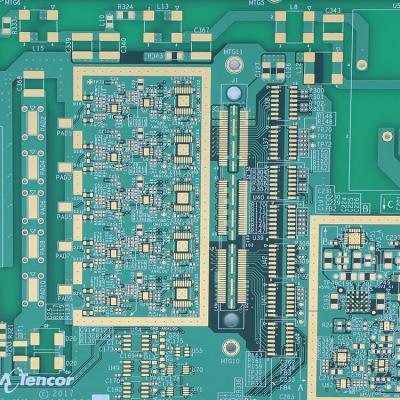

Realizing the highest light output may lead to increased heat. PCB, which has improved thermal resistance, extends the service life of the finished product. Qualified manufacturers will provide you with excellent protection and reduce calories and component reliability.

Advantages of aluminum substrate

Compared with other substrates, the aluminum substrate has a unique advantage:

Not so expensive. Aluminum is the soil of various climate, so it is easy to dig and refine it. This makes minerals and refining significantly reduced costs than other metals. In addition, the manufacturing costs related to products using aluminum substrates are also low. Aluminum substrate is also a substitute for radiator.

Environmental friendly aluminum is a non -toxic, recyclable metal. From manufacturers to terminal consumers, using aluminum in PBC can help healthy earth.

Better heat transfer. High temperature is the cause of severe damage to electronic products. Aluminum conductive and transmitting heat away from key components to minimize damage to the printing circuit board.

Very durable aluminum is stronger and durable than substrate materials such as ceramics and glass fibers. It is very solid and can reduce accidental damage in the entire manufacturing process and the processing and daily use.

Light: Considering its durability, aluminum is very lightweight. It increases the strength and elasticity of PCB without increasing the extra weight.

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd